The vapour permeability problems and applications of biomaterials

The vapour permeability problems and applications of biomaterials

Vapour permeability is a critical factor in the use and production of biomaterials, particularly in medical, environmental, and bioengineering applications. It refers to the ability of a material to allow the passage of water vapour through its structure. Here’s an in-depth look at its importance and role in biomaterials:

1. Moisture Management in Wound Healing

Role: In wound care, vapour-permeable biomaterials (such as hydrocolloid dressings, alginates, or hydrogels) are crucial for maintaining an optimal moisture balance. This promotes faster healing while preventing excessive moisture accumulation that could lead to maceration or infections.

Importance: vapour permeability allows the controlled release of moisture from the wound bed, supporting a moist wound environment, which is known to accelerate cell migration, reduce pain, and enhance tissue repair.

2. Breathability in Tissue Engineering and Implants

Role: In tissue engineering, scaffolds made from biomaterials must often be breathable to ensure gas exchange (oxygen and carbon dioxide) and moisture management. This is vital for maintaining the viability of cells embedded within or surrounding the scaffold.

Importance: High vapour permeability allows the diffusion of oxygen and other gases necessary for cellular respiration, while also removing excess moisture, preventing hypoxia, and reducing infection risks. It is also critical in biodegradable implants, where the release of degradation by-products through vapour diffusion is necessary for proper function.

3. Comfort and Functionality in Biomedical Textiles

Role: Biomedical textiles used in applications like surgical gowns, drapes, and implantable fabrics must have a balance between vapour permeability and barrier properties (e.g., fluid repellency). This ensures comfort for the wearer while protecting from infections.

Importance: High vapour permeability in textiles allows sweat and moisture vapour to escape, keeping skin dry and reducing the risk of skin irritation or pressure ulcers in long-term applications like bandages or patient clothing.

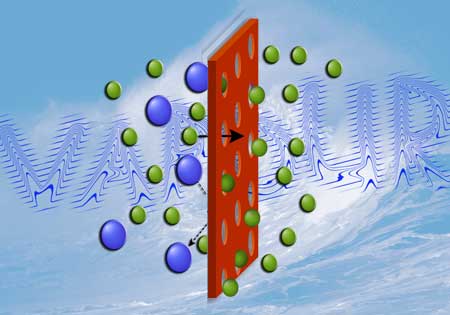

4. Controlled Drug Delivery Systems

Role: In certain controlled-release drug delivery systems, biomaterials with vapour-permeable properties allow the gradual release of therapeutic agents by managing the diffusion of water vapour through the material. This can influence the rate at which drugs are released into the body.

Importance: The permeability of the biomaterial can be tuned to regulate drug release rates, which is important for creating sustained, controlled delivery profiles in medications for chronic conditions.

5. Biodegradable and Eco-Friendly Materials

5. Biodegradable and Eco-Friendly Materials

Role: vapour permeability plays a significant role in the development of biodegradable packaging materials or biofilms. Biomaterials used in packaging or environmental protection are designed to decompose or be absorbed over time, and permeability to water vapour is essential for facilitating this process.

Importance: Allowing vapour to permeate accelerates the breakdown of biodegradable polymers by promoting microbial activity and moisture-induced degradation. This property is vital for compostable materials and helps reduce environmental pollution.

6. Prevention of Biofilm Formation

Role: In medical devices, such as catheters and stents, vapour-permeable biomaterials can reduce the risk of biofilm formation by allowing moisture to escape and maintaining a dry surface, thereby reducing bacterial colonization.

Importance: The ability to control moisture levels through vapour permeability is an important strategy to mitigate the risk of infections associated with implantable medical devices, where stagnant moisture can facilitate microbial growth.

7. Personal Protective Equipment (PPE)

Role: For biomaterials used in PPE, such as face masks, gloves, and gowns, vapour permeability ensures comfort and breathability while still protecting against the transmission of infectious agents.

Importance: Effective vapour permeability ensures that heat and moisture are dissipated, preventing discomfort, overheating, or moisture buildup in the fabric, which could potentially reduce the effectiveness of the protective material.

8. Environmental Sustainability

Role: Many biomaterials are designed to be used in environmentally sustainable applications, such as in the creation of biodegradable packaging or agricultural films. vapour permeability is a critical factor in determining how these materials interact with their environment.

Importance: In agriculture, for example, vapour-permeable biomaterials are used in films to control humidity around plants, allowing water vapour to pass while protecting crops. Similarly, in packaging, vapour permeability ensures that items like food maintain their quality by allowing moisture to escape, reducing spoilage.

9. Barrier and Breathability Balance

Role: A key challenge in biomaterial design is achieving the right balance between barrier properties (e.g., preventing the entry of harmful microbes or substances) and vapour permeability (allowing the material to "breathe").

Importance: This balance is especially important in medical applications, where biomaterials must protect against infections while still maintaining comfort and a healthy physiological environment. Examples include bandages that protect against external contaminants while allowing moisture vapour to escape, reducing the risk of skin maceration.

Conclusion

Vapour permeability is a vital property in biomaterials, ensuring the appropriate balance between moisture management, breathability, protection, and biodegradability. Whether in medical devices, wound dressings, personal protective equipment, or environmental materials, controlling vapour permeability allows biomaterials to perform efficiently while meeting the biological, mechanical, and environmental demands of their applications.

Click here for a press release